Meet Printsyst: The Only AI 3D Printing Expert You’ll Ever Need

Printsyst co-founders Itamar and Eitan Yona are brothers, and they represent our first startup from Israel as members of Batch X. They are also the 3rd generation in a family of a printers, carrying their family tradition into the realm of 3d printing. Their startup, Printsyst, is for companies that use 3D printing, but don’t have internal expertise. PrintSYSt is an AI-powered management solution that provides a complete automated 3D printing workflow. Unlike standard existing solutions, PrintSYSt requires no expertise, allowing users to focus on design instead of production.

Itamar, the older brother at 34, plays the role of CEO, and has a degree in Electrical Engineering. He provides professional engineering advice, lectures, and workshops about additive manufacturing worldwide. His articles being published on well-known industry magazines and blogs. Eitan on the other hand focuses his attention on marketing and communication, and can be found frequently on the team’s YouTube channel, connecting with experts and educating his audience on 3D manufacturing.

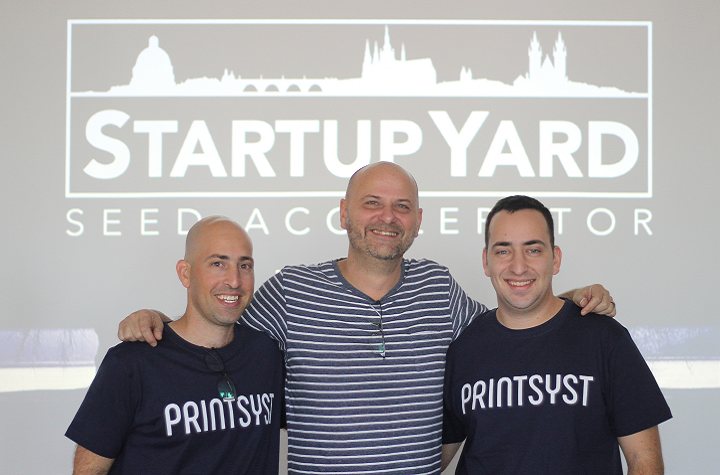

Printsyst Co-Founders Itamar (left) and Eitan Yona (right), with StartupYard CEO Cedric Maloux

Hi Eitan and Itamar. You are not actually our first pair of siblings at StartupYard, but I think people will be interested to know how it is you both came to make 3d printing your focus in life. What’s it like to do this together?

We will answer these questions in one voice, because that’s really the way we are as a team. We know each other so well, it’s like one hand working with the other. It’s muscle memory.

Working with family is unlike anything else. You can have colleagues, and you can have people whom you rely on and you trust, but these are not your family. We are a 3rd generation family in this business. Our grandfather was a printer, our father is a printer. We are carrying that tradition forward, and in that sense we see ourselves as a part of that tradition, just bringing it forward.

Our father taught us growing up that individually, we would never have the strength that we have together. Perhaps you can tie this in with the history of our country and people as well. We have to cooperate as one to get things done. As brothers we are able to learn collectively, and to multiply our strengths.

That is the secret sauce in a family business, which is that you are building upon a foundation that is rock solid. In most tech startups, we think this is missing. That sense of belonging to the industry and the sense that you are born to do what you do is very appealing. Our family is not just in the printing business, but rather we are in the technology business, and always have been. The technology just changes. The business part is not so different.

It’s fun as well. We can laugh at and scream at each other, and change directions in 10 seconds. We don’t have to forgive each other for every mistake. We can be angry, and we can share our feelings with each other. One can rely on the other.

Is there a downside to the family dynamic?

Sure. We are very monomaniacal about our work. It can be hard to stop talking about work and switch to other topics. How are your kids? What did you do this weekend? We get very comfortable talking about work topics, to the point where the separation of work and life is a bit blurry.

But again, this is in the family for generations. Our parents worked together all our lives, with our grandparents too. Life and family is business. There is no distinction sometimes. I don’t know if you consider that healthy. Maybe it’s good for some people and not good for others. We make it work. We are happy with what we do now.

Do you think that family background, being a 3rd generation printing family, gives you an advantage over others who come into this business from a different background, such as in computer science or manufacturing? What are the intangibles of a printer’s life experience?

So, it’s important to emphasize that we are technologists, by tradition. Printing is just the technology we know. A family business is not something that should stay the same for all time. That is not progress. Instead, a family business gives you the roots you need and the stable base you need to grow with much higher confidence and the right connections from the beginning.

It may seem like we are departing from tradition. Our father and grandfather were in 2D printing (Printing Press). We are in 3D. It’s a different world. However, our father made the switch from offset to digital printing. That was equally difficult, and equally transformative in its own time. The needs of customers change continually, and having a deep empathy and respect for people is something that takes a lot of life experience.

In that sense, what you do in 3D printing is no different at all from any other kind of printing. People always have the same flaws and the same needs from you. You are the person helping them to take advantage of the technology and see what is possible for them. If 50 years ago it was that they could print a photo or a book, today it’s that they can print something like a pair of glasses. Still, you serve a human need: to start a small business, to realize a creative dream.

That human level is where everything important is happening. The business that can get down to really sharing a bond with the customer and understanding and appreciating them for what they are, is going to be successful. The money will follow. That’s our view.

It seems rare to me in technology to see people follow their parents as role models and mentors

Yes, it is more rare than it used to be. Technology is no longer seen as a trade, but rather as a skillset. So you are not a craftsman or a journeyman, but an engineer. That brings the focus out of customer-minded, traditional practices, and toward institutional ideas and practices. The engineer thinks as the university teaches him to think. Not as his father teaches him to think.

That is not always bad of course, but there is a reason that trades have been passed down from

parent to child for all of time. In the formalization of some knowledge, you will lose that which cannot be written down. I can teach you to code out of a book. I cannot teach you to run a business out of a book. I cannot tell you what use that code will be once you know how to do it. That is experiential, and it is something people can get from their parents, and should get from them.

So in a sense you would like to see the tech business be more conservative?

Maybe. What does this mean, conservative? There is simply a great deal of value in growing up in an industry, just as there is value in coming into an industry fresh with a new perspective. Both approaches must always be considered.

In the “entrepreneur industry” today, ego is heavily monetized. Right? It is all about the founder and the singularity of them and their vision, and how no one else is the same as they are. No one can do what they do. But this is nonsense. This is not how knowledge is gained in the real world or passed on for our shared benefit. We are not islands to ourselves. If you build to last, then what you build is more than you are.

When you look to the great fortunes of the 21st century, it is sad in a way that they belong to people who are in many ways isolated in time and place. They have no sense of their past or future. Disruption in the sense that the technology industry means is often just an ego trip. Technology always changes. It is a question of whether we are better as people, or worse. Do we do good for people, or not?

What attracts you to working on 3d printing in Europe? Why not somewhere else?

Well, of course we were attracted to StartupYard! But also the fact that Europe is a really fertile ground for change and innovation in 3D printing. We see it as somewhere that we can bring a lot of value, and where businesses and people are ready to take advantage of our technology.

We love Israel as well, so we will always be home there. However, 3D printing is not like the old printing business. It is language independent. It is global and digital. So we must be where other companies are doing this work. The business may be global, but being physically present is still very important. We have to make ourselves unavoidable and inescapable for the future of 3d printing.

Let’s talk about the technology because I think most people see 3d printing in a really simplistic way. What is the current state of 3d printing, if you can provide some analogy to traditional printing technology? Are we in the Gutenberg days? The Franklin era?

Yeah, that’s a good question. So decades ago, when our father was taking over the family business, there was no really good software drivers available for professional, quality printing. People who were going digital were doing this stuff on their own. You had to have a very good reason to do that, because the change was very drastic. It was essentially taking everything that you know about printing, and changing all of it.

You want to print digitally? Ok. You need a team of developers, hardware engineers, you need a lot of money to research and test. You basically have to start from zero. People cannot imagine this now, because today you don’t think about PostScript and print drivers, and these things that were hell on people in the printing business for many years.

You have to consider that digital transformation is not a new phenomenon in 2018. It has been going on for decades already. The journey from an offset press, with physical plates printing pages, to a digital laser printer is an enormous change. It is like going from steam power to electric. Everything must change.

Now we face the same level of challenges in 3D printing. To digitize the making of 3D objects. If you will, I think we are in the offset printing era right now of 3D objects. You have injection molds. You have industrial processes that take huge investment and planning to work. You do have 3D printing happening on a small scale, but you lack all the hardware and the essential drivers between the finished object, and the technology itself. And if you are lucky enough and have access to 3D printing, you still need to follow a long learning curve.

That is the problem we are solving at the end of the day. The ease with which you print a page of paper today should be, maybe 15years from now, the same ease you experience printing a pair of glasses or a new doorknob. Whatever you need. Remember printing evolved from handwriting to the printing press, to the digital laser printer in more than 500 years. Manufacturing also is taking a journey from the handmade to the ubiquitously available object in a similar space of time.

Obviously there have been some hype bubbles surrounding 3D printing in the last few years. Do you think we are poised for a major step in the adoption of these technologies now?

It’s true, particularly maybe 10 years ago, that there have been some hype and disappointment around 3D printing. This is necessary to the process, And predictable in a way.

This is a normal thing for new technologies on the adoption curve.

There were lots of ideas, and people doing very cool things with 3D printers, but the technology has not jumped to mainstream adoption for a few specific reasons.

One of them is the materials being used, and that is changing very quickly. People found pretty quickly that the variety of objects and functionalities was limited by the material. Color, strength, consistently, etc. There are many new approaches coming to the physical printing process that will make this much easier.

On the side of software, this is what we are trying to solve. One of the problems that emerged very quickly was that there are many physical parameters to consider when you are printing an object of any size.

Unlike on a piece of paper, you have an object in 3 axis, and you must consider the 4th dimension as well: in which orientation should parts be printed, and even more, what should the internal structure of the parts be?

So that is where AI comes in?

Yes, precisely. AI is needed to run through all these potential variations in the way a thing can be printed, and select the best one for the purpose at hand. That can save a very lengthy process of having to manually determine these factors, or just guess and check to see if it works, which is what people are doing today.

Many hobbyists quickly found out that they could not move from imagining a new object to simply printing it, because the technology required more detail than the imagination supplies. You need hundreds or more parameters to print a 3D object. You must know the thickness of each component. You need to choose internal structures (honeycomb, swiss cheese?) you must know in what orientation to print, and where the piece will be separated from the printer. How fast will it be printed?

So the process of iterating these tiny details in a physical printer is very expensive and time consuming. There were many cases in which people just couldn’t produce prototypes because they couldn’t get the printer to follow a process that created a stable object. That’s a big problem in 3D printing. That’s not a physical obstacle, it’s a software obstacle.

We are using AI to sort that problem out. You have to virtually simulate the infinite combinations of possible approaches to printing an object, and find that ideal process, which is going to be absolutely unique for every single thing you print. One small change to the thickness or the length of something, and a 3D printer must be completely reconfigured to allow for printing a stable version of this new design.

That really destroys your ability to iterate, unless you can be sure that each time you print, you are getting the best version of the object you are trying to make. You can make quite complex parts in 3D printers, and in some cases these parts can serve to replace dozens of other components that were formerly separate pieces in a machine or a piece of furniture. But if you can’t figure out how to stabily print that object, then the 3D rendering is useless. It’s just an idea.

Printsyst is taking that rendering, and making it printable and stable, and useful from the first try. That’s the objective. Break the expertise barrier that stops people from using 3D printing for whatever reason. Democratize manufacturing and make it something accessible to small businesses, entrepreneurs, and individuals.

We know that 3D printing has huge applications for manufacturing and design (such as being able to rapidly build custom parts and eliminate assembly steps). But what kind of impact do you see on consumer lives in the next decade or so?

Much of the impact may go unseen for the near future, to the end user. Many things that were formerly very complex to assemble may begin to be 3D printed, such as electronic components and even parts for cars, furniture, and things like that. But you may not know the difference if you don’t know how to look for it. It will simply allow businesses to deliver these goods cheaper, faster, and in more variety.

Later on, as this technology is further democratized, it can have the same effect that widespread printing had on the spread of literature and businesses around the world. The ability to create something fast, cheap and in good quality with minimal equipment also means you can take a lot of creative risks, and many microbusinesses may be born. Already you see this among some designers, using 3d printing as a bit of a gimmick. It will not be a gimmick forever.

Ultimately, we probably get to the point where an individual is able to order or print parts and object themselves that are customized to their exact needs or the needs of a situation. You know what size shoe you wear, but I bet you don’t know the distance between your temples. So why don’t you? Because knowing that, you can create a pair of glasses that fit you perfectly.

3D printing will mean “mass customization.” This means less waste of energy and materials, less cost to transportation, and ultimately we believe a better environment in which fewer resources are ultimately wasted by overproduction and under-customization.

How can companies who are employing 3D printing start to take advantage of your technology? Where do they get started?

Right now, we are working with small and medium sized enterprises who are using 3D printing to develop and produce new products. These companies don’t have a lot of internal 3d printing expertise, but can bridge that gap with Printsyst.

We also are interested in working with designers, and other entrepreneurs or engineers who want to use 3D printing, but again, don’t want to lose a lot of time learning how to get the most out of a printer or a particular design. We would love to support efforts to build low cost housing, and there are currently many needs from many different types of printers to get them to run more efficiently, and to optimize designs on the go, making each printed part perfect for its exact position and purpose.

Some industries we see getting interested are especially interior designers, architects, and automotive repair as well. 3D printing is great for refurbishing cars or making customized components, so we should see a lot more interest in that direction. Replacement parts, particularly, can be made much faster and exactly to fit.

In the long term, we really believe this technology is going to penetrate everywhere. Eitan spent his military service on a submarine in the Israeli Navy, working mostly on repairs. Imagine having a 3D printer in a submarine so print the exact parts you need. Stock becomes a much easier logistical issue.